Ordinary motor driven vortexers will not create a mixing vortex within a microplate well or vial unless the orbit generated is smaller in diameter than the inside diameter of each well or vial ( download our scientific paper on this subject from our web site ).

Almost all single vortexers can only shake one vial at a time by using a motor driven eccentric platform. When attempting to process multi-well microplates with small well volumes, an adapter required to hold more than 4 plates requires the alignment of multiple eccentrics within the shaker does not allow very small orbits. Mechanical wear is also a recurring problem.

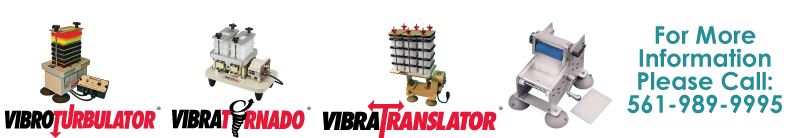

The USC Vibratornado consists of two sets of high endurance leaf springs supporting a pair of shaking platforms that are driven magnetically at 90 degrees to each other. Further, the driving magnets are powered at 90 degrees out of phase with each other causing the sample platform to move in a modified circle. The diameter of this circle can be adjusted remotely and continuously by merely turning a potentiometer dial. An orbit of less than one half millimeter is easily achieved, and will generate a vortex inside the liquid filled wells of a 1536 microplate! A standard machine will vortex 18 such plates at once, providing a throughput of27,648 samples at one time. ( Download our scientific paper on “creating a vortex” from our web site.) There are no wearing or rubbing parts in these machines, hence no wear.